DRIVESHAFTS & DRIVES

Maintaining the drives and driveshafts of your Powerboat is important to ensure they continue to function properly and avoid potential damage or failure. Here are some maintenance tips:

- Clean and lubricate: After each use, clean the drives and driveshafts with freshwater to remove any dirt or debris. Then, apply a light coating of lubricant to the driveshafts and bearings to prevent corrosion and reduce friction.

- Check for wear: Regularly inspect the drives and driveshafts for any signs of wear or damage, such as cracks, rust, or excessive play. Replace any worn or damaged parts immediately.

- Tighten fasteners: Check the fasteners that hold the drives and driveshafts in place, such as bolts or screws, to make sure they are tight. Loose fasteners can cause the driveshafts to vibrate or even detach, leading to damage or failure.

- Align the drives: Make sure the drives are properly aligned with the engines and each other. Misalignment can cause excessive wear on the driveshafts and bearings, leading to premature failure.

- Grease the shaft seals: Grease the shaft seals to prevent water from entering the drives and causing damage.

- Replace the flex cables: Flex cables can wear out over time and cause problems with the steering and throttle control. Inspect the flex cables regularly and replace them if they show signs of wear or damage.

By following these maintenance tips, you can help ensure that the drives and driveshafts of your RC powerboat continue to function properly and last for a long time.

MAINTENANCE OF YOUR ENGINES

Maintaining the marine 2 stroke engines of your RC powerboat is important to ensure they continue to function properly and avoid potential damage or failure. Here are some maintenance tips:

- Regularly check the engine oil level and replace the oil as necessary. Use high-quality, marine-grade 2-stroke oil.

- Check and clean the air filter regularly. Replace the filter if it’s dirty or damaged.

- Inspect the spark plugs regularly and replace them if they are worn or damaged.

- Check and replace the fuel filter as needed. A dirty fuel filter can cause the engine to run poorly or even fail to start.

- Check the fuel lines and fittings for leaks or damage. Replace any damaged or worn components.

- Inspect the propeller for any damage or wear, and replace it if necessary.

- Check the water pump impeller regularly and replace it every season or as recommended by the manufacturer.

- Inspect the exhaust system for leaks or damage, and replace any damaged components.

- Regularly inspect the electrical connections and wiring for any signs of wear or damage.

- Follow the manufacturer’s recommended maintenance schedule, which can include tasks such as cleaning the carburetor, adjusting the idle speed, and checking the timing.

By following these maintenance tips, you can help ensure that your marine Two-stroke engines continue to function properly and last for a long time.

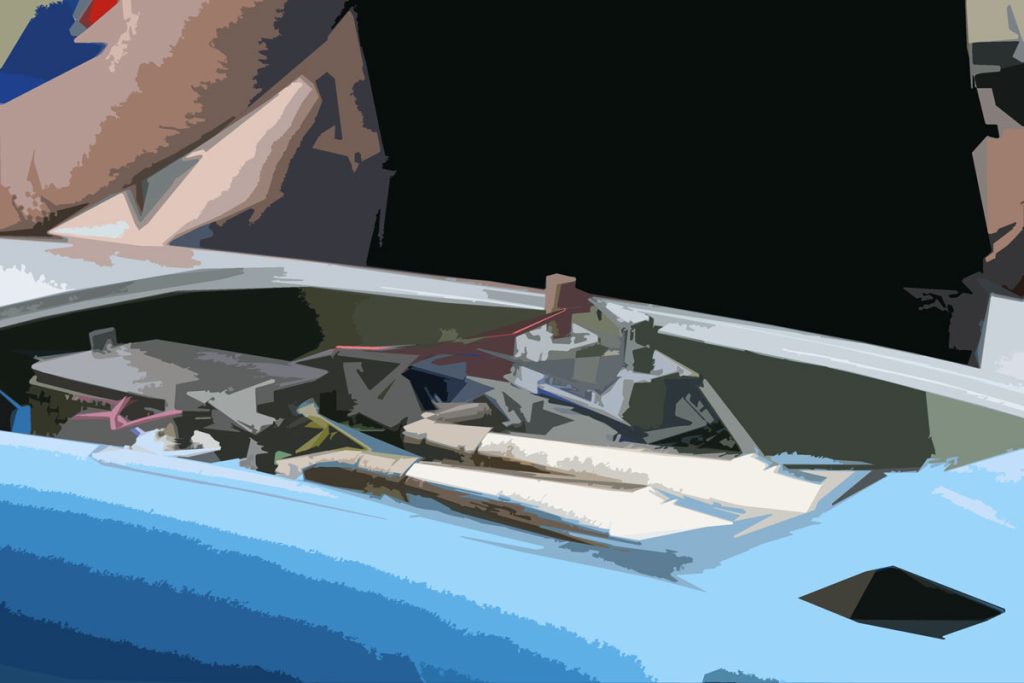

THE RC BOX

here are some maintenance tips for the electric RC components of your powerboat:

- Keep the components clean and free of dust, debris, and moisture. Wipe down the components with a soft, dry cloth after each use, and avoid exposing them to water or other liquids.

- Check the batteries in the radio transmitter regularly, and replace them as needed. Weak or dead batteries can cause problems with the radio system.

- Inspect the antenna on the radio transmitter for damage or wear. Replace the antenna if it is bent, broken, or shows signs of wear.

- Check the wiring and connections on the servos and RC box. Make sure all wires are securely connected, and replace any damaged or worn wiring.

- Lubricate the servo gears and bearings regularly to ensure they operate smoothly. Use a light silicone-based lubricant for this purpose.

- Test the servo operation periodically to ensure they are functioning properly. If you notice any problems with the servos, such as sluggish operation or incorrect movement, replace them immediately.

- Inspect the RC box for signs of damage or wear. Replace the box if you notice any cracks or other damage.

- Store the RC components in a cool, dry place when not in use. Avoid exposing them to extreme temperatures or humidity.

By following these maintenance tips, you can help ensure that your powerboat’s electric components remain in good working condition, helping to ensure safe and reliable operation on the water.

Proper maintenance of the fuel tank is essential to ensure the safe and efficient operation of your RC powerboat. Here are some maintenance tips for the fuel tank:

FUEL TANK

- Keep the fuel tank clean and free of debris. Dirt, water, and other contaminants can damage the engine or clog the fuel system.

- Inspect the fuel tank for leaks, cracks, or other damage. If you find any damage, replace the tank immediately.

- Use high-quality fuel that is recommended by the engine manufacturer. Poor quality fuel can damage the engine or cause it to run poorly.

- Add a fuel stabilizer to the fuel tank if the boat will be stored for an extended period. This will help prevent the fuel from degrading and causing problems with the engine.

- Use a fuel filter to help remove contaminants from the fuel before it reaches the engine. Replace the filter regularly to ensure it is functioning properly.

- Check the fuel lines and fittings for leaks or damage. Replace any damaged or worn components.

- Check the fuel tank vent to ensure it is functioning properly. A clogged or damaged vent can cause problems with the fuel system.

- Regularly inspect the fuel tank for signs of corrosion or rust. If you find any, replace the tank immediately.

By following these maintenance tips, you can help ensure that your fuel tank functions properly and provides clean fuel to the engine, helping to keep it running smoothly and efficiently

TUNED PIPE MAINTENANCE

Maintaining a water-cooled 2-stroke tuned pipe in an RC powerboat involves a few key steps to ensure optimal performance and longevity of the engine and associated components. Here are some general guidelines:

- Check the cooling system regularly: The water-cooled system is critical for keeping the engine at a safe operating temperature. Make sure the water intake and exit are clear and free of debris. Check the water pump and hoses for any leaks or damage.

- Monitor the tuning: Tuned pipes require specific tuning for optimal performance. It’s important to keep an eye on the engine’s performance to ensure it’s not running too lean or rich. Adjustments may need to be made periodically depending on the conditions, such as temperature or humidity.

- Check for wear and tear: Over time, the tuned pipe and exhaust system can become damaged or corroded. Inspect the pipes, connectors, and mounting hardware for any signs of wear or damage. Replace any parts that show excessive wear to prevent further damage.

- Clean the system: Regular cleaning of the tuned pipe and exhaust system can help keep it running smoothly. Use a mild detergent and warm water to clean the exterior of the pipes and remove any debris or buildup.

- Store the boat properly: When not in use, make sure the powerboat is stored in a dry, clean, and protected location. Cover the boat and disconnect the battery to prevent any damage from occurring while it’s not in use.

By following these steps, you can help ensure that your water-cooled 2-stroke tuned pipe is maintained properly and will provide reliable performance for years to come.

GEARBOX

Maintaining a water-cooled gearbox in an RC powerboat involves several steps to ensure its optimal performance and longevity. Here are some general guidelines:

- Check the cooling system regularly: The water-cooled gearbox relies on a water intake and exit system to keep it at a safe operating temperature. Check the water pump and hoses for any leaks or damage, and ensure that the water flow is sufficient to keep the gearbox cool.

- Monitor the lubrication: The gearbox requires regular lubrication to ensure smooth operation and to prevent wear and tear on the gears. Use the manufacturer-recommended lubricant and change it periodically according to the maintenance schedule.

- Check for wear and tear: Over time, the gears and other components in the gearbox can become damaged or worn. Inspect the gearbox and its associated components for any signs of wear or damage, such as cracks or excessive wear on the gears. Replace any parts that show signs of wear to prevent further damage.

- Clean the system: Regular cleaning of the gearbox and its associated components can help prevent the buildup of debris or contaminants that can interfere with its operation. Use a mild detergent and warm water to clean the exterior of the gearbox and remove any debris or buildup.

By following these steps, you can help ensure that your gearbox is maintained properly and will provide reliable performance for years to come. It’s also a good idea to consult the manufacturer’s maintenance guidelines for specific recommendations and maintenance schedules for your particular gearbox model.

THE TWIN STEP DEEP VEE HULL

here are some additional tips for cleaning and maintaining the hull

- Inspect the steps for damage: The steps of a deepvee twinstep hull are critical to the boat’s performance and efficiency. Inspect the steps regularly for any signs of damage, such as cracks or chips in the fiberglass or paint finish. Repair any damage as soon as possible to maintain the integrity of the hull.

- Clean the steps thoroughly: The steps of a deepvee powerboat can be difficult to clean due to their shape and location. Use a soft-bristled brush or sponge and a mild detergent to clean the steps, being careful not to scratch the surface. Rinse the steps thoroughly with fresh water to remove any soap residue.

- Wax the steps: Applying a coat of wax to the steps can help protect the fiberglass or paint finish from UV rays and other environmental factors. Use a marine-grade wax and follow the manufacturer’s instructions for application.

- Check the water intakes: The water intakes on a powerboat are important for cooling the engine and preventing overheating. Inspect the intakes regularly for any signs of blockage or damage. Clear any debris from the intakes and replace any damaged screens or fittings as needed.

- Check the bottom of the hull: The bottom of a twinstep hull is prone to damage from rocks, logs, and other underwater obstacles. Inspect the bottom of the hull regularly for any signs of damage, such as scratches, dents, or punctures. Repair any damage as soon as possible to prevent water from entering the hull and causing further damage.

By following these additional tips, you can help keep the hull and steps of your bigscale rcpowerboat in excellent condition and ensure optimal performance on the water.