RCPOWERBOAT WIKI

Derzeit ist die RCPwiki hauptsächlich in englischer Sprache verfügbar, aber wir freuen uns, Ihnen bald auch eine deutsche Version anbieten zu können. Um Ihnen einen Einblick in unser faszinierendes Hobby zu geben und Sie bestmöglich zu unterstützen, möchten wir Ihnen einige interessante Themen rund um das RC-Powerboot-fahren vorstellen:

Bleiben Sie dran und freuen Sie sich auf weitere spannende Inhalte rund um unser gemeinsames Hobby, das RC-Powerboot-fahren!

PROPELLER DIRECTION

The orientation of the propellers on a Deep-Vee hull with two drives can significantly affect the boat’s performance, handling, and stability. Propellers can be set up to rotate either outwards (away from the centerline) or inwards (towards the centerline). Here are the key differences between these two configurations:

Outward Rotating Propellers:

- Handling and maneuverability: With propellers rotating outwards, the boat may exhibit better handling characteristics, especially in turns. The outward rotation creates a natural tendency for the boat to remain flatter during turns, making it easier to maintain control and prevent sliding or skidding.

- Reduced propeller wash: Outward rotating propellers can produce less turbulence and propeller wash behind the boat, which can be advantageous if you are towing water skiers or wakeboarders.

- Higher top speed potential: Some boat owners and operators report higher top speeds with outward rotating propellers, although this can vary depending on the specific boat and propeller setup.

Inward Rotating Propellers:

- Improved efficiency: Inward rotating propellers can provide better overall efficiency, especially at cruising speeds. The inward rotation can create a more uniform flow of water around the hull, which can result in less drag and better fuel economy.

- Enhanced stability: Inward rotating propellers can improve the boat’s lateral stability due to the inward-directed thrust. This can be particularly beneficial in rough water conditions, where maintaining stability and control is crucial.

- Bow lift: Inward rotating propellers tend to generate more bow lift, which can help the boat plane more quickly and maintain a better running angle. This can lead to a smoother, more comfortable ride in various water conditions.

- Better tracking: Boats with inward rotating propellers often track better in a straight line, as the propeller forces are directed towards the boat’s centerline. This can result in a more stable ride at high speeds or in challenging water conditions.

In summary, outward rotating propellers on a Deep-Vee hull with two drives offer better handling and maneuverability, reduced propeller wash, and potentially higher top speeds. In contrast, inward rotating propellers provide improved efficiency, enhanced stability, increased bow lift, and better tracking. The choice between these configurations depends on factors such as intended use, desired performance, and personal preferences. Boat owners and pilots should consider how these factors apply to their specific needs and goals when deciding on a propeller rotation setup.

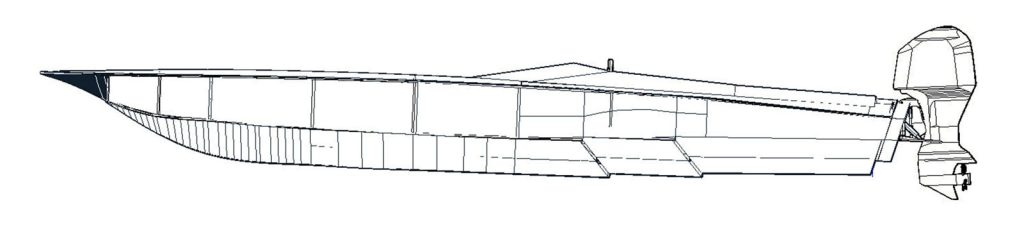

Twin Step Deep Vee Hull

A twin step deep vee hull is a type of boat hull design that features two „steps“ or notches on the bottom of the hull that create air pockets or voids between the steps. This design is typically used for high-performance boats, as the air pockets reduce the amount of surface area in contact with the water, reducing drag and increasing speed.

The deep vee hull design itself is characterized by a sharp V-shaped bottom that allows the boat to cut through waves and choppy water with ease. This provides a smooth and stable ride, even at high speeds.

The addition of twin steps to the deep vee hull design further enhances the boat’s performance by reducing drag and increasing speed. As the boat moves forward, water is forced down into the steps, creating pockets of air that act as a cushion, reducing drag and allowing the boat to travel faster through the water.

Twin step deep vee hulls are commonly used in racing boats, as well as high-performance pleasure boats. However, they can also be found in some commercial and military vessels where speed and maneuverability are important.

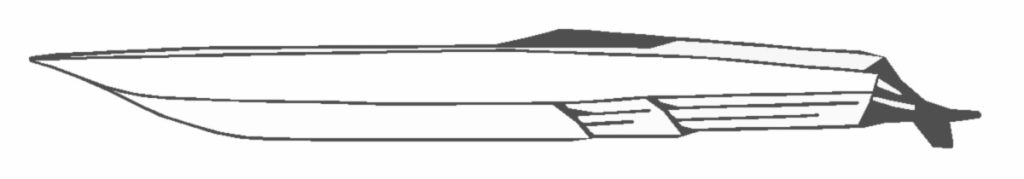

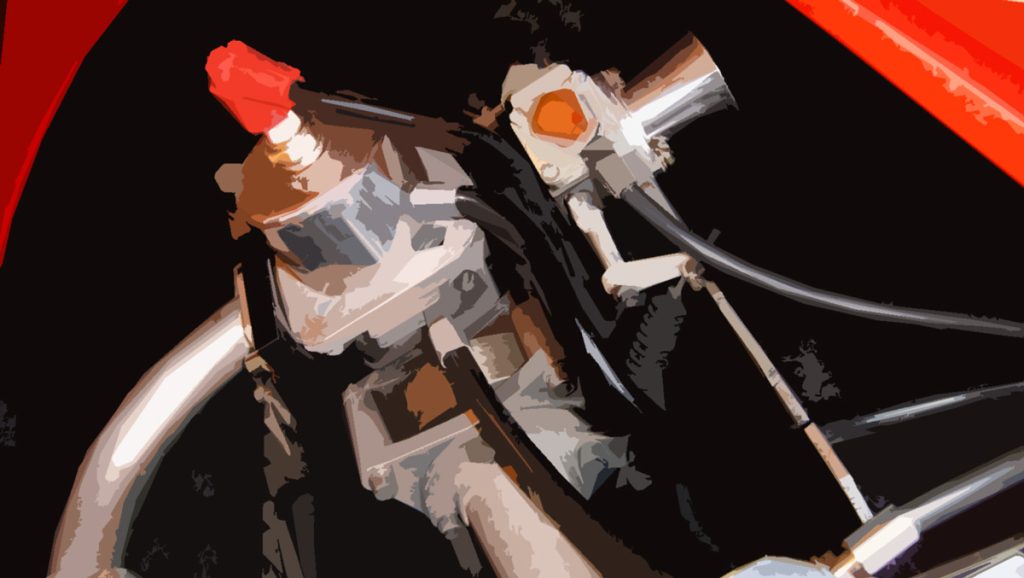

Steerable surface Drives

RC steerable surface drives are a type of propulsion system used in remote-controlled boats. Unlike traditional shaft-driven propellers, these drives use a steerable surface drive unit that sits above the waterline, which makes them more efficient and less susceptible to drag.

The steerable surface drive unit consists of a propeller, a drive shaft, and a surface-piercing skeg that sits just above the waterline. The skeg helps to stabilize the drive unit and allows it to operate more efficiently. The propeller is mounted to the drive shaft and spins freely, providing thrust to move the boat forward.

The key advantage of RC steerable surface drives is their ability to be steered independently of the boat’s rudder. This provides greater control and maneuverability, especially at high speeds. By tilting the drive unit, the boat can be steered left or right, and by adjusting the angle of attack of the propeller, the speed and direction of the boat can be controlled.

RC steerable surface drives are commonly used in racing boats, as they provide high speeds and exceptional maneuverability. However, they can also be found in some recreational boats and scale models, as they offer a unique and exciting way to control a remote-controlled boat.

Powerboat materials

RC powerboats can be made from a variety of materials, including fiberglass, wood, and carbon fiber. Carbon fiber is a popular choice for high-performance RC powerboats due to its strength and light weight.

When it comes to carbon fiber construction, there are a few different terms you may hear, including „GK“ and „carbon rovings.“ GK, or „Geschnittenes Kraus,“ is a German term that refers to a type of carbon fiber cloth that has been cut into small pieces and layered to form a stronger, more resilient material. This type of construction is often used in high-stress areas of the boat, such as the transom or engine mounts.

Carbon rovings, on the other hand, are long strands of carbon fiber that are woven together to create a stronger, more rigid material. Full carbon construction, which uses carbon rovings exclusively, is often used in high-performance RC powerboats that require maximum strength and rigidity.

Carbon fiber construction offers several advantages for RC powerboats. First and foremost, carbon fiber is incredibly strong and light, which allows for faster speeds and better handling. It is also resistant to corrosion, which makes it an ideal material for use in saltwater environments. However, carbon fiber construction can be expensive, and it requires special tools and techniques to work with. As a result, it is typically reserved for high-end RC powerboats designed for racing or other high-performance applications.

Full Scale RC Powerboat

A full-scale RC powerboat is a large, high-performance boat that is operated remotely. These boats are typically designed for racing or high-speed recreational use and are capable of reaching speeds of up to 100 miles per hour or more.

Full-scale RC powerboats are constructed from a variety of materials, including fiberglass, carbon fiber, and Kevlar. These materials are lightweight and strong, allowing the boats to travel faster and more efficiently through the water.

The powerplant for a full-scale RC powerboat is typically a high-performance gasoline engine, although some boats may be powered by electric motors or jet engines. These engines can generate up to 6,000 horsepower or more, providing the boat with the power it needs to reach high speeds.

To control a full-scale RC powerboat, the operator uses a remote control transmitter that sends signals to the boat’s onboard receiver. The receiver then translates these signals into commands that control the boat’s speed, direction, and steering.

Full-scale RC powerboats are designed to provide a thrilling and exciting experience for both the operator and spectators. They are often used in competitive racing events, where they can reach speeds of up to 200 miles per hour on straightaways. However, due to their high speeds and powerful engines, they should only be operated by experienced and skilled operators.

Semi Scale RC Powerboat

A semi-scale RC powerboat is a model boat that is designed to resemble a full-scale boat, but is not an exact replica. These boats are typically smaller in size than full-scale models, and may be powered by electric motors, gas engines, or jet drives.

Semi-scale RC powerboats are constructed from a variety of materials, including fiberglass, wood, and plastic. They are often built from pre-made kits or plans, which can be customized to suit the individual builder’s needs and preferences.

These boats are designed to provide a fun and exciting experience for the operator, while also being easy to control and maneuver. They may be used for recreational boating, as well as in competitive racing events.

One of the advantages of semi-scale RC powerboats is that they can be more affordable and easier to operate than full-scale models. They are also easier to transport and store, making them a popular choice for hobbyists who do not have access to large bodies of water.

However, semi-scale RC powerboats may not be as fast or powerful as full-scale models, and they may not be as durable or long-lasting. They also require regular maintenance and upkeep, just like any other model boat or vehicle.

Overall, semi-scale RC powerboats are a fun and exciting way to enjoy remote-controlled boating, whether for recreation or competition.

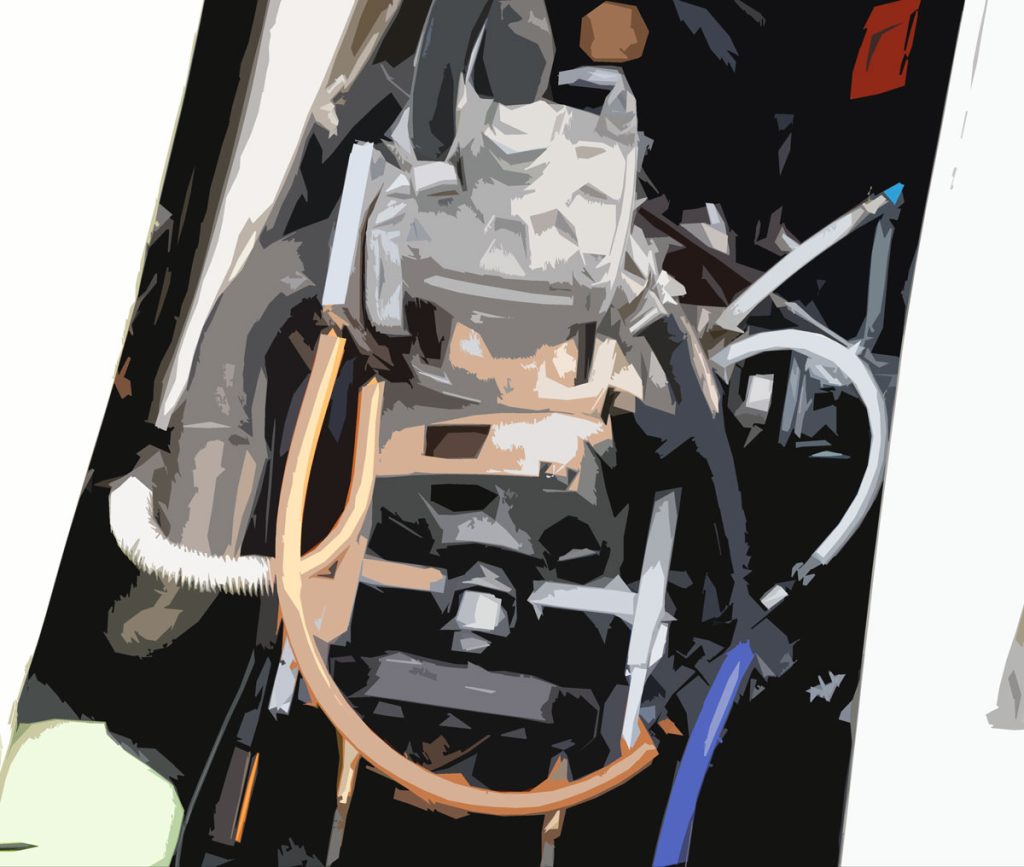

RCMK Engines

RCMK is a brand of high-performance water-cooled 2-stroke engines that are commonly used in RC powerboats. These engines are known for their high power output, reliability, and efficiency, and are designed specifically for use in marine applications.

Water-cooling is an essential feature of RCMK engines, as it helps to dissipate heat and maintain a consistent operating temperature. This is especially important in high-performance RC powerboats, which generate a lot of heat due to their high speeds and heavy loads.

RCMK engines typically feature a dual water-cooling system, which consists of a water jacket surrounding the cylinder and a water-cooled head. The water jacket helps to cool the engine block, while the water-cooled head helps to cool the combustion chamber and valves.

One of the advantages of RCMK engines is their high power output. These engines are capable of producing up to 10 horsepower or more, which allows RC powerboats to reach speeds of up to 50 miles per hour or more. They are also known for their reliability, which is important in marine applications where breakdowns can be dangerous and expensive.

However, RCMK engines do require regular maintenance and upkeep, including oil changes, spark plug replacements, and cleaning of the water-cooling system. They also require specific tuning and adjustment to optimize their performance and ensure that they are running safely and efficiently.

Overall, RCMK water-cooled 2-stroke engines are a popular choice for RC powerboat enthusiasts who are looking for high-performance, reliable engines that can handle the demands of marine applications.

POLINI ENGINES

Polini engines are popular among RC powerboat enthusiasts for their high performance and reliability. The Polini H2O engine is a water-cooled two-stroke engine that is commonly used in RC powerboats. It is designed to deliver high power output and fast acceleration, while also being durable and easy to maintain.

The Polini H2O engine features a liquid cooling system that helps to regulate the engine’s temperature and prevent overheating. The engine is also designed with a high-performance carburetor and tuned exhaust system, which help to optimize fuel delivery and exhaust flow for maximum power.

To install the Polini H2O engine in an RC powerboat, specific engine mounting components may be required, as well as a compatible drive system and propeller. The engine may also require some tuning and adjustment to achieve optimal performance and reliability.

Overall, the Polini H2O engine is a popular choice among RC powerboat enthusiasts who are looking for a high-performance engine that is capable of delivering fast speeds and reliable performance.

ZENOAH ENGINES

enoah is a brand of engines produced by Japanese manufacturer Komatsu Zenoah. The PUM series of engines are water-cooled, two-stroke engines that are designed to power a variety of boats, including fishing boats, pleasure craft, and racing boats.

Some features of the Zenoah PUM water-cooled engines for boats include:

- Available in a range of sizes and power outputs, from 23cc to 45cc and 1.6 horsepower to 4.2 horsepower.

- Electronic ignition for reliable starting and smooth operation.

- High-capacity water cooling system to maintain engine temperature and prevent overheating.

- Lightweight design for improved boat performance and handling.

- Low-emission design to meet environmental regulations.

In addition, Zenoah offers a range of accessories and replacement parts for their PUM engines, including propellers, carburetors, fuel tanks, and spark plugs.

If you are considering using a Zenoah PUM engine in your boat, it is important to consult the manufacturer’s recommendations and specifications to ensure that you select the appropriate engine size and power output for your particular boat and intended use.

Tuned Pipe and silencer

In a powerboat with a two-stroke engine, the tuned pipe and silencer are important components that play a crucial role in the engine’s performance.

A tuned pipe is a specially designed exhaust system that helps to increase the engine’s power and efficiency. It works by using the pressure waves created by the engine’s exhaust to create a scavenging effect that helps to draw more air/fuel mixture into the cylinder during the engine’s intake stroke. This scavenging effect can help to increase the engine’s horsepower output and improve overall performance.

The shape and length of the tuned pipe are critical to its effectiveness. The pipe needs to be tuned to match the engine’s RPM range, and the length needs to be carefully calculated to optimize the pressure wave timing.

The silencer, also known as a muffler, is responsible for reducing the noise produced by the engine. The silencer works by using a series of chambers and baffles to reduce the noise generated by the engine’s exhaust gases.

In an RC powerboat, the tuned pipe and silencer are typically sold as a single unit. The combination of the two components is designed to optimize the engine’s performance while keeping noise levels within acceptable limits.

RUDDER

A rudder is an important component of an RC powerboat that helps to steer and control the direction of the boat. The rudder is typically located at the rear of the boat and is connected to a servo that is controlled by the transmitter. When the driver uses the transmitter controls to turn the rudder, the water flowing over the rudder creates a force that helps to turn the boat in the desired direction.

There are many different types of rudders that can be used on RC powerboats, depending on the size and type of boat, as well as the intended use and performance characteristics. Some rudders are designed to be more efficient at high speeds, while others may be better suited for low-speed maneuvering and agility. The size and shape of the rudder can also affect the boat’s handling and stability, and may need to be adjusted or customized for optimal performance in different conditions.

Strut & Driveshaft

The strut is another important component of an RC powerboat that helps to support and control the propeller. The strut is typically a metal or plastic bracket that is attached to the hull of the boat and holds the propeller shaft in place. The strut is designed to keep the propeller aligned with the centerline of the boat, while also providing support and stability.

The design and construction of the strut can affect the performance of the RC powerboat in several ways. For example, the angle and length of the strut can affect the angle of attack of the propeller, which can influence the boat’s speed and handling. The material and strength of the strut can also affect its durability and resistance to vibration and stress.

Some RC powerboat enthusiasts may choose to modify or customize their struts in order to achieve better performance or to fit specific propellers or motors. Different types of struts, such as adjustable or strut-mounted rudders, may also be used to improve the handling and maneuverability of the boat.

The drive shaft is another important component of an RC powerboat that transmits power from the motor to the propeller. The drive shaft is typically a long, cylindrical metal rod that is connected to the motor at one end and the propeller at the other end. As the motor turns the drive shaft, it rotates the propeller and propels the boat through the water.

The design and construction of the drive shaft can affect the performance and durability of the RC powerboat. For example, the diameter and material of the drive shaft can affect its strength and resistance to bending or breaking under high speeds or loads. The length of the drive shaft can also affect the boat’s handling and stability, and may need to be adjusted or customized for optimal performance in different conditions.

In some cases, the drive shaft may be modified or upgraded to achieve better performance or to fit different types of motors or propellers. For example, a flex shaft drive system may be used in high-performance RC powerboats to reduce vibration and improve efficiency, while a solid drive shaft may be used in larger boats or boats that require more torque.

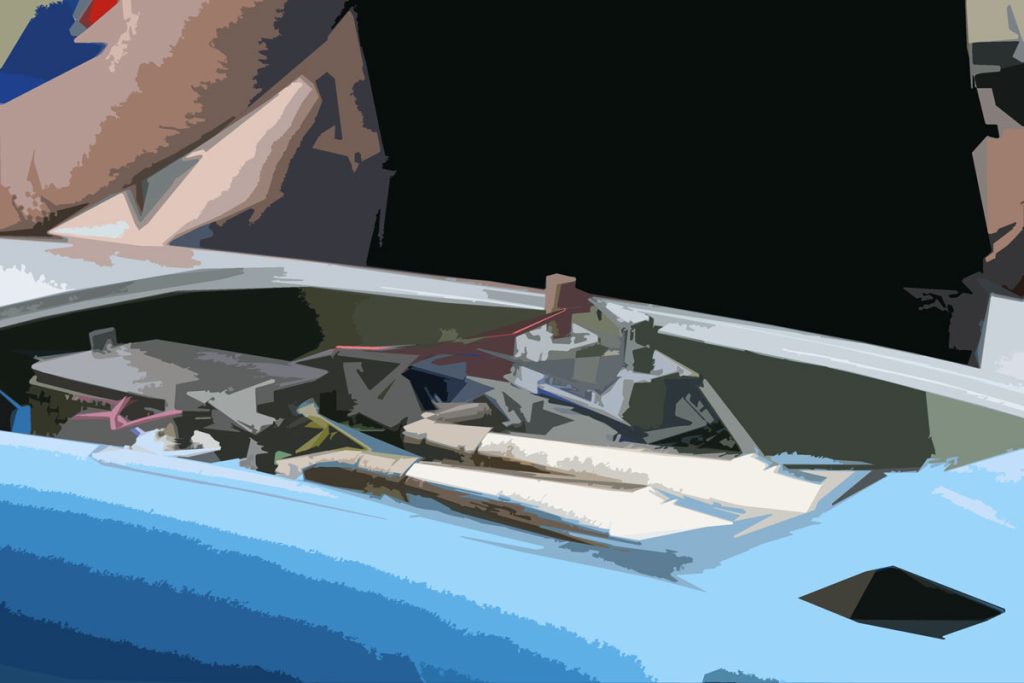

engine mounting

The engine mounting is an important component of an RC powerboat that holds the engine securely in place and transfers the power to the drive train. The engine mounting can be a simple bracket or a more complex assembly that includes multiple components, such as a plate, bolts, spacers, and rubber dampers.

The design and construction of the engine mounting can affect the performance and reliability of the RC powerboat. For example, the engine mounting must be strong enough to hold the engine securely in place, while also allowing for some flexibility and vibration dampening. The material and thickness of the mounting plate, as well as the size and strength of the bolts and spacers, can all affect the strength and durability of the mounting.

In addition to the basic mounting components, some RC powerboat enthusiasts may also choose to add additional features or modifications to the engine mounting to improve performance or fit specific engines. For example, adjustable engine mounts may be used to adjust the position or angle of the engine to optimize performance, while custom-made engine mounts may be used to fit non-standard engines or to accommodate special features like water cooling or tuned pipes.

Futaba FHSS

Futaba FHSS (Frequency Hopping Spread Spectrum) is a radio control technology developed by Futaba Corporation, a leading manufacturer of radio control systems for model airplanes, helicopters, boats, and cars. FHSS is a form of spread spectrum modulation that uses frequency hopping to improve the reliability and security of radio communications.

In FHSS technology, the transmitter and receiver hop between different frequencies within a given frequency band, rapidly changing the frequency of the signal to avoid interference and reduce the risk of signal loss. This helps to ensure that the radio signal remains clear and strong, even in areas with high levels of electromagnetic interference.

Futaba FHSS technology is used in a wide range of radio control products, including transmitters, receivers, and servos. It is designed to provide high-speed response and precise control, making it a popular choice for hobbyists and professional users alike.

One of the benefits of FHSS technology is its reliability and security. The frequency hopping technique helps to prevent interference from other devices and ensures that the radio signal remains strong and clear, even in crowded areas. This makes it a popular choice for use in areas with high levels of electromagnetic interference, such as industrial or urban environments.

Overall, Futaba FHSS technology is a reliable and effective radio control system that provides precise control and high-speed response for a wide range of model vehicles and aircraft.

SERVOS

High-torque servos are often used in RC powerboats to control functions such as steering, throttle, and trim tabs. These servos are designed to deliver high levels of torque, allowing them to operate effectively even under heavy loads or high speeds.

There are several popular brands of high-torque servos that are commonly used in RC powerboats, including Futaba, Savox, and Hitec. These servos typically range in torque ratings from around 50 oz-in to over 300 oz-in, depending on the specific model and application.

When selecting high-torque servos for an RC powerboat, it is important to consider factors such as the specific application, the size and weight of the boat, and the desired level of performance. For example, larger boats with heavier loads may require higher-torque servos, while smaller boats with lighter loads may be able to use lower-torque servos.

In addition to torque, other factors to consider when selecting high-torque servos for an RC powerboat include speed, precision, durability, and waterproofing. Servos with metal gears, dual ball bearings, and waterproofing are often preferred for use in RC powerboats, as they are better able to withstand the harsh conditions of marine environments.

RC POWERBOAT RACE TRACK

An RC powerboat race course can be set up in many different configurations, depending on the size of the boats and the specific rules of the race. One popular race course for RC powerboats is a 400-meter oval course, which is typically set up with buoys or markers to indicate the course boundaries and turns.

In a 400-meter oval course, boats race around the perimeter of the course, making two left turns and two right turns. The course is typically set up to be wide enough to accommodate multiple boats racing side by side, with clear lanes marked to prevent collisions and ensure fair racing.

RC powerboat races on a 400-meter oval course typically involve multiple heats or rounds, with boats competing to achieve the fastest lap times or overall race times. Races may also involve various classes or divisions of boats, with different rules or restrictions based on boat size, engine type, or other factors.

Overall, a 400-meter oval course is a popular and challenging race course for RC powerboats, requiring a combination of speed, maneuverability, and skill to navigate the turns and maintain a fast pace throughout the race.

Race Weather

RC powerboat races can take place in a variety of weather conditions, depending on the preferences and safety considerations of the organizers and participants. However, certain weather conditions can make racing more challenging or risky, and may require additional precautions or modifications to the race course or boats.

In general, RC powerboat races can be held in calm or moderate weather conditions, with boats typically able to handle mild wind or waves. However, strong winds, heavy rain, or other extreme weather conditions can make racing difficult or dangerous, and may require postponement or cancellation of the race.

To ensure safety and fair competition, RC powerboat races may be modified or rescheduled in response to changing weather conditions. This may involve adjusting the course layout or race format, or postponing the race to a later date when weather conditions are more favorable.

Overall, RC powerboat racing is a fun and exciting sport that can be enjoyed in a variety of weather conditions, provided that appropriate safety measures are taken and precautions are followed. With proper preparation and attention to weather conditions, racers can enjoy competitive and thrilling racing throughout the year.

The FSR Classes

- FSR 3.5cc: This class of model raceboat features a nitro-powered engine with a displacement of 3.5 cubic centimeters (cc). These boats can reach speeds of up to 60 mph and are typically around 30 inches in length.

- FSR 7.5cc: This class of model raceboat features a nitro-powered engine with a displacement of 7.5cc. These boats can reach speeds of up to 70 mph and are typically around 40 inches in length.

- FSR 15cc: This class of model raceboat features a nitro-powered engine with a displacement of 15cc. These boats can reach speeds of up to 80 mph and are typically around 48 inches in length.

- FSR 35cc: This class of model raceboat features a nitro-powered engine with a displacement of 35cc. These boats can reach speeds of up to 100 mph and are typically around 60 inches in length.

- FSR-H: This class of model raceboat features a gas-powered engine and has no displacement limit. These boats can reach speeds of up to 85 mph and are typically around 48 inches in length.

- FSR-O: This class of model raceboat features an electric motor and has no displacement limit. These boats can reach speeds of up to 50 mph and are typically around 36 inches in length.

Note: It’s worth mentioning that the specifications and rules for these classes may vary depending on the specific race or organization.

Build your RC Powerboat

To build an RC powerboat with two gas 2-stroke engines and steerable surface drives, you will need the following components:

- Hull: You will need a suitable hull for your RC powerboat. The hull should be designed to accommodate two gas engines and have enough space for the steerable surface drives.

- Engines: You will need two gas 2-stroke engines. The engines should be of the same type and power to ensure balanced performance.

- Fuel tank: You will need a fuel tank to hold the fuel for your engines. The fuel tank should be large enough to provide sufficient fuel for both engines to run for the desired amount of time.

- Radio control system: You will need a radio control system that can control both engines and the steerable surface drives. The radio control system should be compatible with your boat and provide a reliable connection between the boat and the controller.

- Propellers: You will need two propellers that are designed to work with gas engines. The propellers should be matched to the engines to provide optimal performance.

- Steerable surface drives: You will need two steerable surface drives that can be controlled by the radio control system. The surface drives should be designed to work with your hull and provide the desired level of steering control.

- Servos: You will need servos to control the steering of the surface drives. The servos should be compatible with your radio control system and be able to provide enough power to move the surface drives.

- Batteries: You will need batteries to power the radio control system and the servos. The batteries should be chosen based on the power requirements of your system and the desired runtime.

- Exhaust system: You will need an exhaust system to vent the exhaust gases from the engines. The exhaust system should be designed to work with your engines and meet any noise regulations in your area.

- Cooling system: You will need a cooling system to keep the engines from overheating. The cooling system should be designed to work with your engines and provide sufficient cooling for prolonged use.

Overall, building an RC powerboat with two gas 2-stroke engines and steerable surface drives can be a complex project, and it’s important to ensure that all the components are compatible and properly installed for optimal performance and safety.

EPOXY RESIN

Epoxy resins are a type of thermosetting plastic that can be used as a matrix material for composites. Composites are materials made from two or more constituent materials with different physical or chemical properties, which when combined, create a new material with improved performance characteristics.

Epoxy resins are commonly used in composites because they are strong, lightweight, and resistant to moisture, chemicals, and heat. They can be used to bond together a variety of reinforcement materials, including fabrics made from carbon, glass, kevlar, and rovings.

Carbon

Carbon fabric is made from carbon fibers, which are thin, strong, and lightweight. Carbon fiber composites have a high strength-to-weight ratio and are commonly used in aerospace and high-performance applications.

Fiber Glass

Glass fabric is made from glass fibers, which are also thin and lightweight but not as strong as carbon fibers. Glass fiber composites are commonly used in marine, automotive, and construction applications.

Kevlar

Kevlar fabric is made from aramid fibers, which have a high strength-to-weight ratio and are highly resistant to impact and abrasion. Kevlar composites are commonly used in ballistic armor, sports equipment, and aerospace applications.

ROVINGS

Rovings are bundles of continuous fibers that can be used in composite manufacturing. They can be made from a variety of materials, including carbon, glass, and kevlar, and can be used to create composite structures with high strength and stiffness.

The choice of fabric and resin combination will depend on the specific application requirements, including the desired strength, stiffness, weight, and other performance characteristics. Different combinations of fabric and resin can be used to create composites with a wide range of properties, making them suitable for a variety of applications.

PROCESSING METHODS

Vacuum infusion is a composite manufacturing technique that uses vacuum pressure to infuse resin into a dry reinforcement material such as carbon, glass, kevlar, or rovings. The process involves placing the dry reinforcement material into a mold and sealing it with a vacuum bag. A vacuum pump is then used to evacuate the air from the mold, creating a vacuum. The resin is then introduced into the mold and drawn into the reinforcement material under the pressure differential created by the vacuum. The resulting composite is then cured to create a strong, lightweight, and durable part.

The combination of vacuum infusion with epoxy resins and various fabric types can lead to several benefits. The use of vacuum infusion allows for better control of the resin-to-fiber ratio, leading to a more consistent and uniform composite. It also helps to eliminate voids and air pockets that can weaken the composite structure. The use of epoxy resins provides high strength, stiffness, and durability while maintaining a low weight, making them ideal for high-performance applications. Different fabric types can be used to tailor the composite’s properties to the specific application requirements, allowing for a wide range of applications.

The combination of vacuum infusion with epoxy resins and various fabric types has become popular in industries such as aerospace, automotive, marine, and wind energy. It offers several advantages over traditional composite manufacturing techniques, such as hand lay-up, including higher strength-to-weight ratios, improved dimensional stability, and reduced material waste.